Thought Leadership

February 2023

Measuring, Monitoring and Verification for Carbon Storage

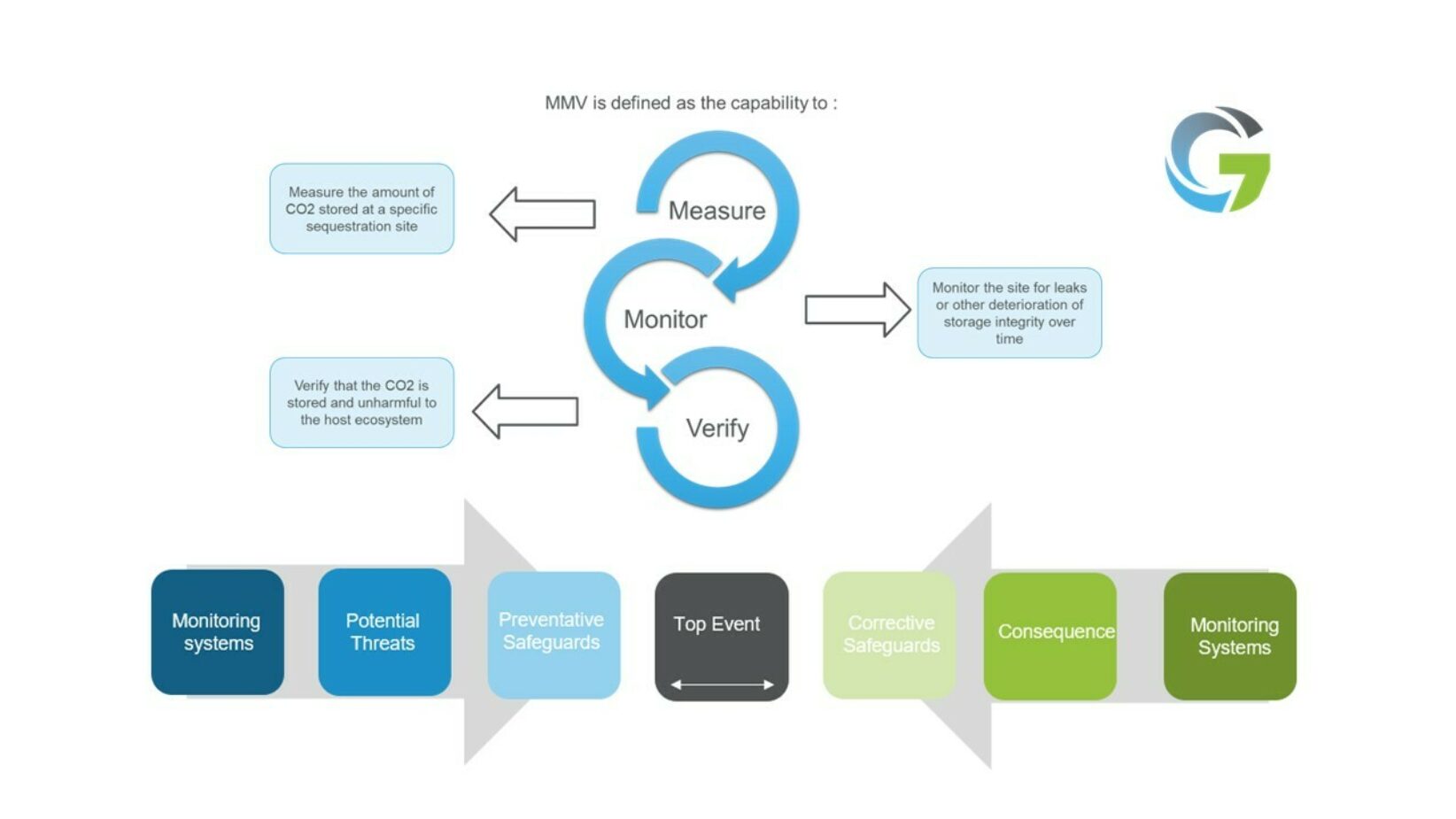

MMV activities are required throughout the lifecycle of a carbon storage (CS) licence including prior to the CS permit award and following site closure.

MMV is defined as the capability to:

- Measure the amount of CO2 stored at a specific sequestration site

- Monitor the site for leaks or other deterioration of storage integrity over time

- Verify that the CO2 is stored and unharmful to the host ecosystem

MMV activities are required throughout the lifecycle of a carbon storage (CS) licence including prior to the CS permit award and following site closure.

There is no one size fits all solution. MMV activities must be tailored to clearly identify carbon storage risks and consider store type, geometric arrangements/ scenarios, injection strategies, seabed conditions etc.

An effective monitoring plan must be site specific, risk-based and adaptive. From an operator's perspective, monitoring must yield clear answers to the above requirements to allow operational decisions to be taken based on monitoring results. The migration of the injected CO2 plume in the reservoir is uncertain and its monitoring is equally challenging. The role of MMV planning is critical in the development of high CO2 contaminant fields. It substantiates that injected CO2 in the reservoir is intact and safely stored for hundreds of years after injection and possesses minimum to no risk to health, safety and the environment.

Examples of field specific risks and preventative safeguards might be:

- Reactivation of overburden faults and caprock failure would be mitigated by injection being maintained below reservoir pressure

- Subsidence can be caused by pressure depletion and a safeguard measure for this would be subsidence monitoring and GPS with periodic measurements from 3D DAS VSP* and OBN**.

- Leakage along well bores (legacy & injectors) would require continuous monitoring using CO2 analyser, soil sampling at well head, annulus pressure etc

MMV could be based on a bowtie containment risk assessment where potential mechanisms that could lead to loss of containment are investigated, and mitigation options are identified. Barriers to reduce the likelihood of a hazard escalation (i.e., a leakage event) can take the form of monitoring technologies combined with corrective actions. Monitoring technologies in an MMV programme are comprehensive and cover all relevant phases (pre-injection, injection and post-injection) and domains (marine environment, geosphere, wells, etc.)

The main tasks in risk management are:

- Identify project risks (threats and opportunities)

- Assess the potential consequence including risk probability for each risk

- Decide and prioritise on mitigation actions

- Follow up the risks and the corresponding mitigating actions

Early monitoring is critical to detect trigger elements that can possibly lead to severe containment failure. Technology used should give confidence that unexpected emissions to the environment can be detected and characterized in a timely and cost-efficient manner to limit escalation of unintended consequences.

Seismic surveys remain the primary geophysical tool of choice for imaging the subsurface. In order to monitor the CO2 plume migration within the reservoir, it is understood that seismic is the most useful technology. Reprocessed old surveys (>15yrs) are unlikely to adequately address risks. Seismic monitoring is reliant upon consistent, repeatable acquisition and careful processing. Simulation models are most accurate with regular update of direct observations. Time-lapse seismic data (4D DAS-VSP & MAZ***) can be used to monitor the development of the CO2 plume and migration inside the reservoir. By actively illuminating the plume (e.g., deploying active acoustic methods with sources such as 4D DAS -VSP) gives the advantage of being able to operate in the higher noise areas that may be expected around injection sites, but this comes at the cost of increased complexity, power consumption and price.

Environmental monitoring strategy for a CO2 storage site should be closely linked to a subsurface containment risk-assessment, investigating all potential site-specific leakage paths. This would be the premise for a comprehensive risk-based Measurement, Monitoring & Verification (MMV) plan including well and subsurface technologies and environmental monitoring elements for the assessed leakage risks. The number and frequency of technologies deployed in the MMV plan is proportional to the quality of barriers in place (e.g. number of subsurface seals, additional storage units, quality of plugs in abandoned wells, etc.) and the severity of potential impacts. It is important to remember that CO2 storage projects rely on in-well (e.g. pressure and temperature) and subsurface monitoring data to identify a potential leakage event long before it reaches the overburden, seabed or overlying ocean. Should an unexpected subsurface migration occur, MMV data would trigger contingency monitoring and corrective measures which would rely on marine monitoring technologies and modelling techniques.

In conclusion, a strong Monitoring, Measurement and Verification (MMV) plan is crucial for the clear identification of the site specific carbon storage risks, early detection of containment breaches and detailing the risk based approach to deployment of mitigation measures. There are currently a number of existing and in-development monitoring technologies that address different aspects of MMV, but it's critical to assess them in terms of applicability, durability, ease of operation & maintenance, and life-cycle cost to the project.

* DAS VSP - Distributed Acoustic Sensing Vertical Seismic Profiling

** OBN - Ocean Bottom Node

***MAZ - Multi Azimuth Survey